Blacksmith Shop

The blacksmith shop's been pretty quiet all summer due to our barn building project. But now that the barn logs have been removed, and with an ox team in need of equipment to pull, Kit has been busy in his blacksmith shop.

His first task was to build a sled for the team to pull, so training could continue.

He ripped one 2 x 10 x 8-foot pine board in half, cut it to 6- foot lengths for runners, and 2-foot lengths for cross bracing. His shop is not wired for electricity at this time so he uses extension cords to run the power equipment. The arch welder in the background was not available nor necessary to complete this project.

A cross-brace, tightly fit into the notched runners.

Kit salvaged 1/8th inch sheet metal and cut it into strips to attach to the bottom of the runners.

He then built eight right angle brackets to make sure the wood cross bracing does not rack.

These are the outside runner brackets Kit punched for carriage bolts. The square punch (right) used for punching the carriage bolt holes, was forged from a leftover piece of S7 tool steel many years ago. Kit uses the soap (far right) to slowly cool fore punches, fullering tools, and pritchels used in horseshoe construction, or in this case sled construction:)

The junior crew was enlisted to peel the pole for the sled tongue.

Kit then forged hooks out of leftover pieces of ½-inch rebar from the barn project . . .

And threaded them to accept nuts. These he will attach to the outside of the sled runners to secure loads.

One piece hitch pins were forged, split, and turned out on the anvil. He had about 10 feet of ¼-inch x 1-inch flatbar stock left from forging sliding plate shoes for reigning and cutting horses. Kit used this stock for the hitch pins, outside runner brackets, and angle braces which were bolted together.

And presto hitch pins, don't you love technology, it makes everything seem so fast and simple?!

Next, Kit devised a way to attach the tongue to the sled. This is where this 4½-inch ring and bolt came into play. The creation of these interlocking pieces required forge welding the ring.

First Kit shaped a straight piece of ½-inch round rod into a circle, a feat in itself to my way of thinking!

But to the well-practiced arm and hammer it was but a few strokes.

It's ROUND! Amazing! Now to prepare it for welding the two ends together.

First, a trip to the forge to heat it up again.

And wow! Did it ever get HOT!

The ends to be welded are now scarfed just slightly, and overlapped.

Flux (borax) is added in the area to be welded to keep the scale from building up on that area. And then it's put back in the forge to become white hot, a point just before melting.

With it white hot, the two sides are smashed together and hopefully they weld together.

The resultant golden ring!

Kit then attached the hook and ring to a metal bracket made from a leftover piece of 3/8-inch x 1¼-inch bar-stock, (think draft horse shoes), which he inlet and fit between the sled runners. He also fashioned stake pockets along with a few other small details. By creating most of the hardware for this project in his blacksmith shop, the product is one of a kind, in a class of its own. But it was not accomplished in a day or two as planned. This project took the better part of four days. There were still oxen to work, cows to milk, and snow to be shoveled on each end of the day.

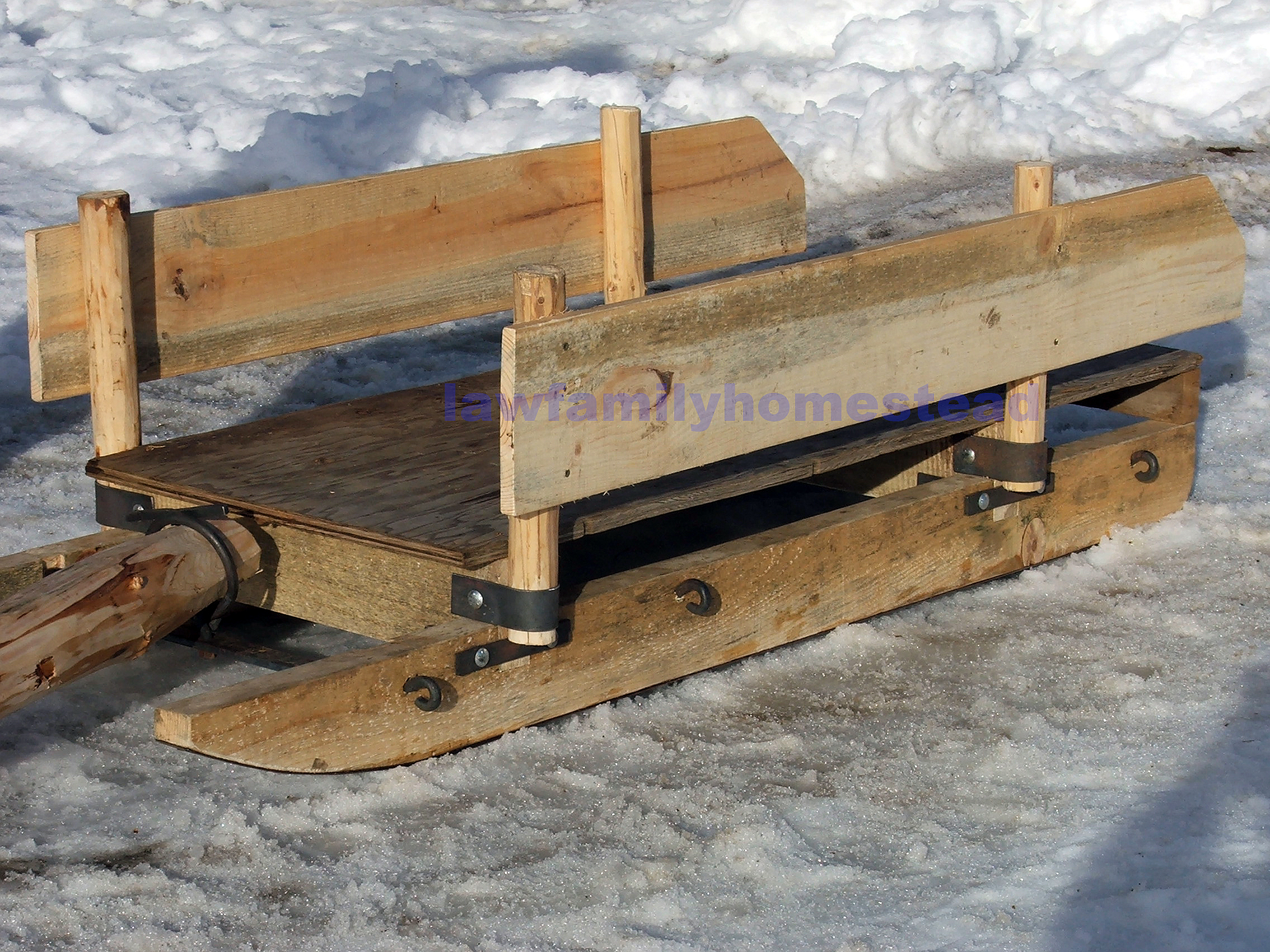

And now to show you all these pieces assembled in their final places.

Here, in this side view, you can see the steel plate on the runners, the hooks to tie on loads, stake pockets and a pin on top of the cross bracing to allow a "flatbed" to be put on or taken off.

This is a closeup of the angle bracing, and stake pockets.

Assembled and ready for hauling small logs, firewood, bales of hay, etc. Kit built this small sled capable of hauling up to 500-pound loads. He will likely build a larger sled in the future to match the growth of the oxen's capabilities.

Flatbed assembled.

Sideboards were deemed a good addition.

The whole project finally finished and tested as functional! Sled weight without the tongue, 100 pounds.